-

Nippon Cloid MFG Co., Ltd.

Address

1-6-3 Akanehama, Narashino, Chiba

TEL:81-47-452-8181

FAX:81-47-452-8182

MAIL:sales@cloid.co.jp

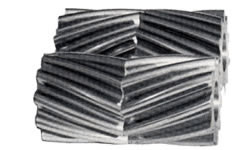

With the abovementioned material and mechanics, low noise and low cavitation are achieved even at high speeds, and a pump with corrosion resistance, long life, and high efficiency is obtained.

-

Our company’s ellicloid gear pump

-

Involute gear pump

-

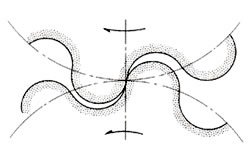

Ellicloid tooth profile

-

Double helical ellicloid gear

-

1. The locking phenomenon does not occur, and thus, the vacuum phenomenon and extreme high-pressure phenomenon are also circumvented.

-

2. Liquid easily flows into the inter-tooth capacity as the opening is wide and the inside becomes narrower; thus, high-viscosity liquid transfer or high-speed rotation becomes easy.

-

3. The discharge and torque are constant at any moment during the rotation, and the causes for the vibration and noise have been removed.

-

4. The sliding ratio is very small, 1/20 or less than that of an involute pump, and the ratio at each mesh point is almost constant. Thus, there are no problems caused by abrasion. Therefore, the engagement is similar as with a rolling contact.

-

5. There is no limit for the minimum number of teeth; thus, the number of teeth can be decreased for a high-viscosity liquid in order to increase the space between the teeth. Furthermore, the peripheral velocity can be decreased to increase the hydraulic efficiency.

-

6. Because there is no enclosed volume and the number of teeth is decreased by making the teeth module larger, the vacuum level is high, and it is easy to maintain 80% volume efficiency in a 700 mm Hg vacuum.

-

7. Due to the above, we can obtain a gear pump that is quiet, does not cause foaming of liquids, is highly efficient, and has a long life.

-

1. The enclosed volume of the engaging part changes as the gear rotates, and when it becomes smaller (Fig. A), extremely high pressure is generated, which causes stress to the bearing that can lead to vibrations and noise. When the volume expands (Fig. C), the enclosed volume causes a vacuum, and the air in the transfer liquid separates out, causing air bubbles.

-

2. As can be seen in the figure, the inter-tooth capacity at the opening of the engaging part is narrow, which causes cavitation when liquid enters; this in turn causes vibrations, noise, and pitting corrosion, resulting in lower efficiencies.

-

3. Because the sliding ratio of the gear is high and the changes at the engaging point are large, the abrasion of the gear is increased, which leads to lower capabilities and power damage.

-

4. Because there is a limit for the minimum number of teeth, the number of teeth cannot be decreased below a certain level, and thus, the weight and volume increase.

-

Ni: 90%–92% , P: 8%–10%, providing an excellent corrosion resistance.

-

The plating used has a much better resistance than that in electroplating. In addition, by applying heat treatment, it becomes as good as or better than that of hard chromium plating.

-

The adhesive force on mild steel is 24 kg/mm2, which is approximately 2.5 times greater than that of hard chromium.

-

Prevents the seizure and gall phenomenon caused by friction between metals such as titanium and 18-8 stainless steel.

-

The film covering is perfect, and the accuracy is within ±10% with respect to the required thickness.

-

It reaches a maximum of 500 HV as plated and 1000 HV after heat treatment.

-

It is effective against cavitation erosion.

Composite Kanigen, a coating together with fine powders such as diamond or SiC, has excellent corrosion and abrasion resistance.

-

●Performance table

Type Pump permittable rotating speed(min-1) Maximum rotation speed Maximum pressure 300 500 750 1,000 1,500 T JT RT Discharge rate(lit/min) min-1 MPa T-04 6 10 15 20 30 1,500 1 T-06 RT-06 12 20 30 40 60 1,500 1 T-10 JT-10 RT-10 30 50 75 100 150 1,500 1 T-14 JT-14 RT-14 45 75 110 150 225 1,500 1 T-20 JT-20 RT-20 60 100 150 200 300 1,500 1 T-24 JT-24 RT-24 90 150 225 300 - 1,200 1 T-30 JT-30 RT-30 150 250 375 500 - 1,200 1 T-40 JT-40 RT-40 210 350 525 700 - 1,200 1 T-50 JT-50 RT-50 270 450 675 900 - 1,200 1 T-60 JT-60 RT-60 450 750 1,125 1,500 - 1,200 1 T-70 RT-70 720 1,200 - - - 1 T-100 RT-100 1,350 2,250 - - - 1 -

●Materials

Part names Standard material Other material Casing FC250 SCS13 SCS14、SCS16、FCD、SC Gear S45C SCS304 SUS316、SUS316L、SACM、SUS440C Shaft S45C SUS304 SUS316、SUS316L、SACM Bearing BC Carbon Teflon・Ceramic -

●Liquid applied

Viscosity 1~1,000,000cP that's all Temperature -40~400℃ Liquid type Food, Chemistry, and other fields

-

This is a method wherein the pump is driven by a motor through a shaft coupling. If the motor is directly connected, then a 4 pole or 6 pole motor is used. In the case of high-viscosity liquids, the speed is low; thus, a geared motor can be directly connected.

-

This is a method wherein the pump is driven by a motor via a belt normally at a decreased speed. This is a method in which the rotation speed is selected and changed using pulleys when the motor-direct-connection scheme provides too high rotation speed or cannot provide a desired discharge amount.